We the civil engineers has a special relation with the concrete. Now a days almost all the structures are made with concrete due to its durability and easy construction. There are lots many advantages and it is widely used now in the whole world. If we want to define the concrete like our way then we can say that it is a mixture of cement, aggregates, sand and required proportion of water which forms a mixture to give it a definite shape. This mixture has a property of getting harden itself by the process of hydration.

Properties

Components

Components

We the civil engineers has a special relation with the concrete. Now a days almost all the structures are made with concrete due to its durability and easy construction. There are lots many advantages and it is widely used now in the whole world. If we want to define the concrete like our way then we can say that it is a mixture of cement, aggregates, sand and required proportion of water which forms a mixture to give it a definite shape. This mixture has a property of getting harden itself by the process of hydration.

Properties

Components

Components

Once I had an opportunity of visiting a bridge construction site in Bangladesh. The location of the construction site is given below:

It was situated beside a floating bridge. The construction is still going on as of April 2024. The bridge has two abutments and four piers. Two of the piers fall in the middle. We have experienced pile driving in the abutments. Let’s share something new with you that I have learned from that day.

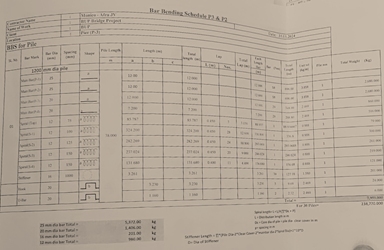

Bar Bending Schedule (BBS): It is provided to the labour to understand the quantity of reinforcement cutting length. Here the shape and requirement are mentioned so they can work by watching that document. It also helps to identify the requirements and reduce the wastage of the rebar in the construction site. The demand for the total quantity of rebar from the shop was done in phases so it is easier to understand from the bar bending schedule how much reinforcement is required now.

BOQ: BOQ means the Bill of Quantity. Here all the items are noted according to the required quantity. It includes everything about a project. No items will be purchased which is not in BOQ. According to the BOQ, the construction bill is given to the contractor. A photo of BOQ is given below:

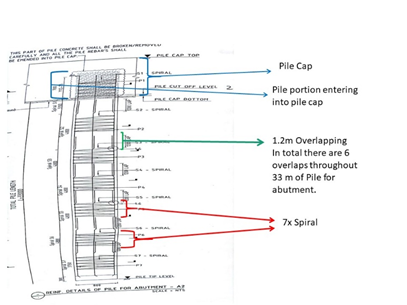

Pile Design: Pile driving is going on in the project. No pre-casted pile is used here. All the pile is cast in situ. The reinforcement case preparation is going on. We have seen the spiral reinforcement construction and how the bundled bar is used. Another thing is new for us that is the stiffener. Another spiral bar is used inside the bundled bar as a stiffener. It provides more stability to the structure.

Here the detailed design of the pile is given. At the upper portion the part of the pile which is entering into the pile cap. From here the cutoff length of the pile is determined.

Spirals: The spiral bars are manually prepared by a wheel. The wheel is shown in the photo.

Bentonite: Bentonite is given surrounding the borehole to resist seepage. It is kept in the containers and mixed in the white-colored mixer. They are poured by the workers and the bags are similar to the cement bags. Bentonite plays a vital role in ensuring the safety, efficiency, and success of pile hole construction by stabilizing the excavation, lubricating pile installation, sealing the excavation, supporting underwater operations, and potentially offering environmental protection.

Pile driving is presently underway as part of the ongoing building of the bridge that will span the lake. Although the employment of novel methods such as stiffeners and cast-in-situ piles is encouraging. A bridge construction is a complex matter. It is not like the building. The components are different and design needs a very expert hand. By this visit we have a hands on experience about the bridge construction. It will create immense impact on our educational journey.